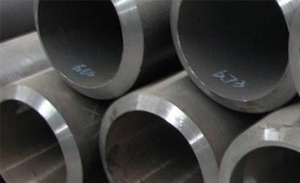

Carbon Steel Pipe ASTM A 106 Gr C Pipe Suppliers

Trio Steel provides a complete range of Carbon Steel Pipe ASTM A 106 Gr C pipes that are innovative in nature and can be customized according to consumer needs. Carbon Steel Pipe ASTM A 106 Gr C pipes provided by Trio Steel are of high quality and durable in nature. Carbon Steel Pipe To ASTM A 106 Gr C Pipe, Stainless Steel Seamless pipes & Tubes, Carbon Steel Seamless Pipes & Tubes and Alloy Steel Seamless Pipes & Tubes are the carbon tubes that are available in our extensive range.

Serving the requirements and demands of various industries, Trio Steel believes in making the best products and is therefore a leading supplier in the production of Carbon Steel pipes. We use state of the art technology for the manufacturing of our pipes.

For Our Customers:

- Customer service provided at Trio Steel is of the highest standard.

- Material used in pipe production is of high quality.

- Equipment is updated and regularly maintained.

- You will get exactly what you need and when you need it.

- Cost effective and high quality Carbon Steel Pipe ASTM A 106 Gr C pipes is supplied.

Carbon Steel Pipe To ASTM A 106 Gr C Pipe Quick Details

- Company Name: Trio Steel

- Country/Region: India

- FOB Price: US $1500-5000 / Metric Ton

- Port: Nhava Sheva Port Mumbai

- Main Products: Seamless Pipes & Tubes, Welded Pipes & Tubes, Stainless Steel Tube, API 5L Pipes

- No.of Employees: 20 – 40 People

- Year Established: 1999

- Certification: ISO 9001, ISO 14001 & OHSAS 18001

Carbon Steel Pipe ASTM A 106 Gr C pipes are used in the construction of petrochemical plants, power plants, oil and gas refineries, boilers and ships wherein fluids are transported.

Sizes (Seamless): 1/2″ NB – 60″ NB

Sizes (ERW): 1/2″ NB – 24″ NB

Sizes (SAW): 16″ NB – 100″ NB

Wall Thickness available:Schedule 20 – Schedule XXS (heavier on request) up to 250 mm thick.

| Specification | A106 NPS 1/8 — 48 ANSI Schedules to 160 | ||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Scope | Covers SEAMLESS carbon steel nominal wall pipe for high-temperature service, suitable for bending, flanging and similar forming operations.

NPS 1 1/2 and under may be either hot finished or cold drawn. NPS 2 and larger shall be hot finished unless otherwise specified. |

||||||||||||||||||||||||

| Kinds of Steel Permitted For For Pipe Material |

Killed Steel Open-hearth Electric-furnace Basic-oxygen |

||||||||||||||||||||||||

| Hot-Dipped Galvanizing |

Not covered in specification. | ||||||||||||||||||||||||

| Permissible Variations in Wall Thickness |

The minimum wall thickness at any point shall not be more than 12.5% under the nominal wall thickness specified. | ||||||||||||||||||||||||

| Chemical Requirements |

|

||||||||||||||||||||||||

| Tensile Requirements |

Seamless Grade A Grade B Grade C Tensile Strength, min., psi…………………….. 48,000 60,000 70,000 Yield Strength, min., psi………………………. 30,000 35,000 40,000 |

||||||||||||||||||||||||

| Hydrostatic Testing | Inspection test pressures produce a stress in the pipe wall equal to 60% or specified minimum yield strength (SMYS) at room temperature. Maximum Pressures are not to exceed 2500 psi for NPS 3 and under and 2800 psifor the larger sizes. Pressure is maintained for not less than 5 seconds. | ||||||||||||||||||||||||

| Permissible Variations in Weights per Foot | Weight of any length shall not vary more than 10% over and 3.5% under that specified. NOTE — NPS 4 and smaller — weighed in lots. Larger sizes — by length |

||||||||||||||||||||||||

| Permissible Variations in Outside Diameter | Outside Diameter at any point shall not vary from standard specified more than–

|

||||||||||||||||||||||||

| Mechanical Tests Specified | Tensile Test — NPS 8 and larger — either transverse or longitudinal acceptable Smaller than NPS 8 — weighed in lots. Larger sizes — by length. Flattening Test — NPS 2 and larger. Bending Test(Cold) — NPS 2 and under.

|

||||||||||||||||||||||||

| Number of Tests Required |

|

||||||||||||||||||||||||

| Lengths | Lengths required shall be specified on order. No “jointers” permitted unless otherwise specified. If no definite lengths required, following practice applies: Single Random — 16′ – 22′. 5% may be 12′ – 16′ Double Random — Minimum length 22′, Minimum average 35′. 5% may be 16′ – 22′. |

||||||||||||||||||||||||

| Required Markings on Each Length(On Tags attached to each Bundie in case of Bundled Pipe) | Rolled Stamped or Stenciled (Mfgrs. option)

|

||||||||||||||||||||||||

| General Information | Unless otherwise specified, pipe furnished with plain ends. Purchaser may specify NDE Surface finish standards are outlined in specification. in lieu of hydrostatic test or neither |

Hydrostatic Testing

The inspection test pressures create a stress in the wall of the pipe that goes to about 60% of the SYMS (specified minimum yield strength) at room temperature. 2500 psi for NPS3 and under 2800 psi for larger sizes are the maximum pressures that aren’t supposed to be exceeded. Pressure is maintained for 5 seconds or more.

Mechanical Tests Specified

Tensile Test — NPS 8 and larger — either transverse or longitudinal acceptable

Smaller than NPS 8 — weighed in lots. Larger sizes — by length.

Flattening Test — NPS 2-1/2 and larger.

Bending Test (Cold) — NPS 2 and under.

| Degree of Bend | Diameter of Mandrel | |

| For Normal A106 Uses | 90 | 12 x nom dia. of pipe |

| For Close Coiling | 180 | 8 x nom dia. of pipe |

Application of Carbon Steel Pipe ASTM A 106 Gr C pipes

Carbon Steel is a pipe that is mainly used in engineering applications, even that of a critical nature. It is also applied in the automotive industry. Other products of carbon steel include the steel used in LPG cylinders, corrosion resistant steel, auto grades, boiler quality, etc.