TRIO STEEL IS A LEADING MANUFACTURER, SUPPLIER AND EXPORTER OF Threaded Flanges.

We provide a complete and best quality range of Threaded Flanges.Threaded Flanges are used in constructions, food industry, pharmaceutical industry, petrochemical industry, automotive industry, municipal and decorative purposes. All Threaded Flanges are individually covered so that the premium quality of materials is retained and there are no damges in the last stages of production.

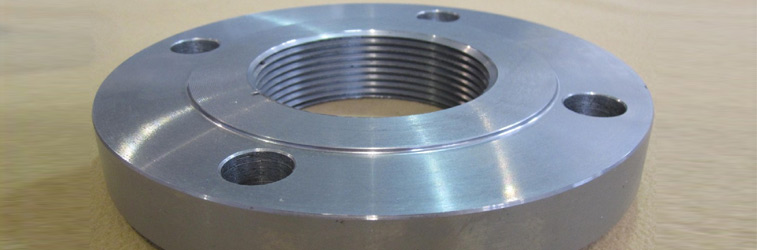

Threaded Flanges Description

Other Name: Threaded Flanges, Screwed Flanges, NPT Flanges, B16.5, ASTM A105, CNC Screwed, 1/2-24, 150, 300

Threaded pipe flanges are similar to slip-on pipe flanges except the bore of threaded pipe flanges has tapered threads. Threaded pipe flanges are used with pipes that have external threads.

Standard: ANSI, ASME, ASA B16.5

Model: Threaded Screwed Flanges, NPT Flanges

Size: 1/2” – 24”

Material: ASTM A105, CARBON STEEL, High Nickel Alloys

Supply Ability: 3000Ton/Month

Process: Forged, Forging

Packing: Plywood Pallets

Payment Terms: T/T, L/C, D/P

THREADED FLANGES, SCREWED FLANGES, A105, RF, CLASS 150, CLASS 300, NPT FLANGES, 1/2″-24″, monthly output 3000 ton.

Norms & Types:

(1) CLASS 150, A105, 1/2″ – 24″, Threaded Flanges, Screwed Flanges, B16.5, NPT, THREADED, ASTM A105.

(2) CLASS 300, A105, 1/2″ – 24″, Threaded Flanges, Screwed Flanges, B16.5, NPT, THREADED, ASTM A105.

Material:

1) CARBON STEEL ASTM A105

Surface Antirust:

Surface antirust 1: Antirust light oil

Surface antirust 2: Black paint coating

Surface antirust 3: Yellow paint coating

Surface antirust 4: Galnavized (Hot Dipped Galvanized or Cold Galvanized or Electro Galvanized)

Surface Finish:

Surface finish 1: Stock finish

Surface finish 2: Sprial serrated

Surface finish 3: Two or three grooves (Water Lines)

Surface finish 4: Smooth finish

Threaded Flanges Dimensions & Tolerances

| Class | 150 | 300 | 400 | 600 | 900 | 1500 | 2500 |

| Diameter – A | 30 | 38 | 38 | 38 | 38 | 38 | 43 |

| Diameter – D | 90 | 95 | 95 | 95 | 120 | 120 | 135 |

| Thickness – B | 9.6 | 12.7 | 14.3 | 14.3 | 22.3 | 22.3 | 30.2 |

| 11.2 | 14.3 | 20.7 | 20.7 | 28.7 | 28.7 | 36.6 | |

| Diameter – G | 35.1 | 35.1 | 35.1 | 35.1 | 35.1 | 35.1 | 35.1 |

| Diameter – K | 60.3 | 66.7 | 66.7 | 66.7 | 82.6 | 82.6 | 88.9 |

| Height – H | 14 | 21 | 22 | 22 | 32 | 32 | 40 |

| 15.6 | 22.6 | 28.4 | 28.4 | 38.4 | 38.4 | 46.4 | |

| Bolt Holes | 4 | 4 | 4 | 4 | 4 | 4 | 4 |

| Diameter – L | 15.9 | 15.9 | 15.9 | 15.9 | 22.2 | 22.2 | 22.2 |

| Stud Bolts Diameter x Length | |||||||

| Diameter (in) | 1/2 | 1/2 | 1/2 | 1/2 | 3/4 | 3/4 | 3/4 |

| Length (mm) | 55 | 65 | 75 | 75 | 110 | 110 | 120 |

——————– > NPS <---------------------

Dimensional Tolerances of Threaded Flanges ASME B16.5

| Outside Diameter ≤ 24 = 1.6 mm | > 24 = ± 3.2 mm |

Inside Diameter Within Limits on Boring Gauge |

| Diameter of Contact Face 1.6 mm Raised Face = ± 0.8 mm 6.35 mm Raised Face, Tongue & Groove / Male-Female = ± 0.4 mm |

Drilling Bolt Circle = 1.6 mm | Bolt Hole Spacing = ± 0.8 mm Eccentricity of Bolt Circle with Respect to Facing ≤ 2½ = 0.8 mm max. | ≥ 3 = 1.6 mm max. |

| Outside Diameter of Hub ≤ 12 = + 2.4 mm / – 1.6 mm | ≥ 14 = ± 3.2 mm |

Diameter of Counterbore Same as forInside Diameter |

| Thickness ≤ 18 = + 3.2 mm / – 0 | ≥ 20 = + 4.8 mm / – 0 |

Length thru Hub ≤ 18 = + 3.2 mm / – 0.8 mm | ≥ 20 = + 4.8 mm / – 1.6 mm |

Notes

- Dimensions are in millimeters unless otherwise indicated.

- The length of the stud bolt does not include the height of the chamfers (points).

Product Range

Size: 1/8″ NB TO 48″NB.

Class: 150#, 300#,400 #,600#,900#, 1500# & 2500 #

Stainless Steel: ASTM A 182, A 240

Grade: F 304, 304L, 304H, 316, 316L, 316Ti, 310, 310S, 321, 321H, 317, 347, 347H,904L, Duplex stainless steel UNS S31803, 2205, Super Duplex stainless steel UNS S32750

Carbon Steel: ASTM A 105, ASTM A 181

Alloy Steel: ASTM A 182, GR F1, F11, F22, F5, F9, F91

Nickel Alloys: Monel 400 & 500, Inconel 600 & 625, Incolloy 800, 825, Hastelloy C22,C276

Copper Alloys: Copper, Brass & Gunmetal

Threaded Flanges Packaging & Marking

All Threaded Flanges are individually covered so that the premium quality of materials is retained and there are no damges in the last stages of production. We also ensure that we deliver our orders promplty and that the quality remains intact.

All Threaded Flanges have imprints on them to highlight the specification of the pipes.