TRIO STEEL IS A LEADING MANUFACTURER, SUPPLIER AND EXPORTER OF Slip On Flanges.

We provide a complete and best quality range of Slip On Flanges.Slip On Flanges are used in constructions, food industry, pharmaceutical industry, petrochemical industry, automotive industry, municipal and decorative purposes. All Slip On Flanges are individually covered so that the premium quality of materials is retained and there are no damges in the last stages of production.

Slip On Flanges Description

Other Name: SLIP ON FLANGES RF, SLIP ON BOSSED FLANGES, SLIP ON HUB FLANGE, SORF FLANGE

Slip on pipe flanges actually slip over the pipe. These pipe flanges are typically machined with an inside diameter slightly larger than the outside diameter of the pipe.

Standards: ANSI, BS4504, EN1092-1/12, ANSI, ASME, ASA B16.5, SORF

Model: SLIP ON FLANGES, SORF FLANGES, SOFF FLANGES

Size: 1/2” – 48”

Process: Forged, Forging

Packing: Plywood Pallets

Norms & Types

- CLASS 150 SLIP ON FLANGES RF, SORF FLANGES, 1/2″ – 48″, ANSI B16.5, A105, ASTM.

- CLASS 300 SLIP ON FLANGES RF, SORF FLANGES, 1/2″ – 48″, ANSI B16.5, A105, ASTM.

- CLASS 600 SLIP ON FLANGES RF, SORF FLANGES, 1/2″ – 48″, ANSI B16.5, A105, ASTM.

- CLASS 900 SLIP ON FLANGES RF, SORF FLANGES, 1/2″ – 48″, ANSI B16.5, A105, ASTM.

- CLASS 1500 SLIP ON FLANGES RF, SORF FLANGES, 1/2″ – 48″, ANSI B16.5, A105, ASTM.

- CLASS 2500 SLIP ON FLANGES RF, SORF FLANGES, 1/2″ – 48″, ANSI B16.5, A105, ASTM.

- BS 4504 PN16 SLIP ON FLANGES, SORF FLANGES, 1/2″-48″, ASTM A105, FORGED.

- EN1092-1/12 SLIP ON FLANGES, PN16, DN15-DN1000, ASTM A105, P245GH, P250GH, FORGED.

Material

1) Carbon Steel A105 & Stainless Steel SS304, SS316, SS316L & High Nickel Alloys

Surface Antirust:

Surface antirust 1: Antirust light oil

Surface antirust 2: Black paint coating

Surface antirust 3: Yellow paint coating

Surface antirust 4: Galnavized (Hot galvanized or Cold galvanized or Electro Galvanized)

Surface Finish:

Surface finish 1: Stock finish

Surface finish 2: Sprial serrated

Surface finish 3: Two or three grooves (Water Lines)

Surface finish 4: Smooth finish

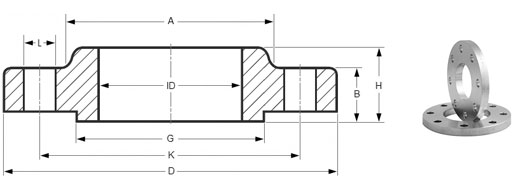

Slip On Flanges Dimensions & Tolerances

Dimensions Slip On Flanges ASME B16.5

NPS 1/2 – I.D. 22.3

| Class | 150 | 300 | 400 | 600 | 900 | 1500 | 2500 |

| Diameter – A | 30 | 38 | 38 | 38 | 38 | 38 | … |

| Diameter – D | 90 | 95 | 95 | 95 | 120 | 120 | … |

| Thickness – B | 9.6 | 12.7 | 14.3 | 14.3 | 22.3 | 22.3 | … |

| 11.2 | 14.3 | 20.7 | 20.7 | 28.7 | 28.7 | … | |

| Diameter – G | 35.1 | 35.1 | 35.1 | 35.1 | 35.1 | 35.1 | … |

| Diameter – K | 60.3 | 66.7 | 66.7 | 66.7 | 82.6 | 82.6 | … |

| Height – H | 14 | 21 | 22 | 22 | 32 | 32 | … |

| 15.6 | 22.6 | 28.4 | 28.4 | 38.4 | 38.4 | … | |

| Bolt Holes | 4 | 4 | 4 | 4 | 4 | 4 | … |

| Diameter – L | 15.9 | 15.9 | 15.9 | 15.9 | 22.2 | 22.2 | … |

| Stud Bolts Diameter x Length | |||||||

| Diameter (in) | 1/2 | 1/2 | 1/2 | 1/2 | 3/4 | 3/4 | … |

| Length (mm) | 55 | 65 | 75 | 75 | 110 | 110 | … |

——————– > NPS <----------------

Dimensional Tolerances of Slip On Flanges ASME B16.5

| Outside Diameter ≤ 24 = 1.6 mm | > 24 = ± 3.2 mm |

Inside Diameter ≤ 10 = ± 0.8 mm | ≥ 12 = + 1.6 mm / – 0 mm |

| Diameter of Contact Face 1.6 mm Raised Face = ± 0.8 mm 6.35 mm Raised Face, Tongue & Groove / Male-Female = ± 0.4 mm |

Outside Diameter of Hub ≤ 12 = + 2.4 mm / – 1.6 mm | ≥ 14 = ± 3.2 mm |

| Diameter of Counterbore Same as for Inside Diameter |

Drilling Bolt Circle = 1.6 mm | Bolt Hole Spacing = ± 0.8 mm Eccentricity of Bolt Circle with Respect to Facing ≤ 2½ = 0.8 mm max. | ≥ 3 = 1.6 mm max. |

| Thickness ≤ 18 = + 3.2 mm / – 0 | ≥ 20 = + 4.8 mm / – 0 |

Length thru Hub ≤ 18 = + 3.2 mm / – 0.8 mm | ≥ 20 = + 4.8 mm / – 1.6 mm |

Notes

- Dimensions are in millimeters unless otherwise indicated.

- The length of the stud bolt does not include the height of the chamfers (points).

Slip On Flanges Packaging & Marking

All Slip On Flanges are individually covered so that the premium quality of materials is retained and there are no damges in the last stages of production. We also ensure that we deliver our orders promplty and that the quality remains intact.

All Slip On Flanges have imprints on them to highlight the specification of the pipes.