TRIO STEEL IS A LEADING MANUFACTURER, SUPPLIER AND EXPORTER OF Lap Joint Flanges.

We provide a complete and best quality range of Lap Joint Flanges.Lap Joint Flange are used in constructions, food industry, pharmaceutical industry, petrochemical industry, automotive industry, municipal and decorative purposes. All Lap Joint Flanges are individually covered so that the premium quality of materials is retained and there are no damges in the last stages of production.

Lap Joint Flanges Description

Other Name: LJ Flanges, LAP JOINT FLANGES, FF, RF, ANSI B16.5, CLASS 150, CLASS 300, ASTM A105

Standard: ANSI, ASME, ASA B16.5, LJ, JIS, DIN, BS4504, SABS1123, EN1092-1, UNI, AS2129, GOST-12820

Size: 1/2” – 24” (DN15-DN2000)

Material: ASTM A105, Carbon Steel, High Nickel Alloys

Supply Ability: 3000Ton/Month

Process: Forged, Forging

Packing: Plywood Pallets

Pressure: ANSI class 150, 300, 600, 1500, 2500, DIN PN6,PN10,PN16,PN25,PN40,PN64,PN100,PN160

Surface Treatment: Anti-rust Oil, Transparent/Yellow/Black Anti-rust Paint,Zinc,Hot dipped Galvanized

ASA B16.5, ANSI B16.5, ASME B16.5, 150# 300# 600# 900# 1500# LAP JOINT FLANGES RF, LAP JOINT FLANGES FF, RF, ASME B16.5, Monthly output 3000Ton.

Norms & Types

1) ASA B16.5 150# LAP JOINT FLANGES, LJ FLANGES, FF, RF, 1/2″ – 24″, ANSI B16.5, ASTM A105.

2) ASA B16.5, 300# LAP JOINT FLANGES, LJ FLANGES, FF, RF, 1/2″ – 24″, ANSI B16.5, ASTM A105.

3) ASA B16.5, 600# LAP JOINT FLANGES, LJ FLANGES, FF, RF, 1/2″ – 24″, ANSI B16.5, ASTM A105.

4) ASA B16.5, 900# LAP JOINT FLANGES, LJ FLANGES, FF, RF, 1/2″ – 24″, ANSI B16.5, ASTM A105.

5) ASA B16.5, 1500# LAP JOINT FLANGES, LJ FLANGES, FF, RF, 1/2″ – 24″, ANSI B16.5, ASTM A105.

Material

1) Carbon Steel ASTM A105 & Stainless Steel ASTM A182 SS304, SS316, SS316L

Surface Antirust:

Surface antirust 1: Antirust light oil

Surface antirust 2: Black paint coating

Surface antirust 3: Yellow paint coating

Surface antirust 4: Galnavized (Hot Dipped Galvanized or Cold Galvanized or Electro Galvanized)

Surface Finish:

Surface finish 1: Stock finish

Surface finish 2: Sprial serrated

Surface finish 3: Two or three grooves (Water Lines)

Surface finish 4: Smooth finish

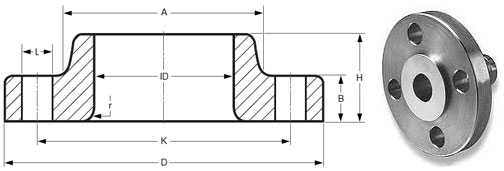

Lap Joint Flanges Dimensions & Tolerances

NPS 1/2 – ID = 22.9 – r = 3

| Class | 150 | 300 | 400 | 600 | 900 | 1500 | 2500 |

| Diameter – A | 30 | 38 | 38 | 38 | 38 | 38 | 43 |

| Diameter – D | 90 | 95 | 95 | 95 | 120 | 120 | 135 |

| Thickness – B | 11.2 | 14.3 | 14.3 | 14.3 | 22.3 | 22.3 | 30.2 |

| Diameter – G | 35.1 | 35.1 | 35.1 | 35.1 | 35.1 | 35.1 | 35.1 |

| Diameter – K | 60.3 | 66.7 | 66.7 | 66.7 | 82.6 | 82.6 | 88.9 |

| Height – H | 16 | 22 | 22 | 22 | 32 | 32 | 40 |

| Bolt Holes | 4 | 4 | 4 | 4 | 4 | 4 | 4 |

| Diameter – L | 15.9 | 15.9 | 15.9 | 15.9 | 22.2 | 22.2 | 22.2 |

| Stud Bolts Diameter x Length | |||||||

| Diameter (in) | 1/2 | 1/2 | 1/2 | 1/2 | 3/4 | 3/4 | 3/4 |

| Length (mm) | 55 | 65 | 75 | 75 | 110 | 110 | 120 |

——————————- > NPS <-----------------------------------

Dimensional Tolerances of Lap Joint Flanges ASME B16.5

| Outside Diameter ≤ 24 = 1.6 mm | > 24 = ± 3.2 mm |

Inside Diameter ≤ 10 = ± 0.8 mm | ≥ 12 = + 1.6 mm / – 0 mm |

| Diameter of Contact Face 1.6 mm Raised Face = ± 0.8 mm 6.35 mm Raised Face, Tongue & Groove / Male-Female = ± 0.4 mm |

Outside Diameter of Hub ≤ 12 = + 2.4 mm / – 1.6 mm | ≥ 14 = ± 3.2 mm |

| Diameter of Counterbore Same as for Inside Diameter |

Drilling Bolt Circle = 1.6 mm | Bolt Hole Spacing = ± 0.8 mm Eccentricity of Bolt Circle with Respect to Facing ≤ 2½ = 0.8 mm max. | ≥ 3 = 1.6 mm max. |

| Thickness ≤ 18 = + 3.2 mm / – 0 | ≥ 20 = + 4.8 mm / – 0 |

Length thru Hub ≤ 18 = + 3.2 mm / – 0.8 mm | ≥ 20 = + 4.8 mm / – 1.6 mm |

Notes

- Dimensions are in millimeters unless otherwise indicated.

- The length of the stud bolt does not include the height of the chamfers (points).

Product range

Lap Joint Flanges Range

½” (15 NB) to 48” (1200NB) in 150 LBS, 300 LBS, 600 LBS, 900 LBS, 1500 LBS, 2500 LBS ASA 150, ASA 300, PN 6,10,16,25,40,64,100,160 ETC.

Available with NACE MR 01-75

Stainless Steel Lap Joint Flanges

Grade : 304, 304L, 304H, 309, 310, 310S, 316, 316Ti, 316 L, 317, 317L, 321, 347, 347 H, 409, 410, 410S, 420, 430L

Duplex Steel Lap Joint Flanges

Grade : 2205 (UNS No. S31803), 2507 (UNS No. S32750)

Nickel Alloy Lap Joint Flanges

Grade : Nickel 200 (UNS No. N02200), Nickel 201 (UNS No. N02201), Monel 400 (UNS No. N04400), Monel 500 (UNS No. N05500), Inconel 800 (UNS No. N08800), Inconel 825 (UNS No. N08825), Inconel 600 (UNS No. N06600), Inconel 625 (UNS No. N06625), Inconel 601 (UNS No. N06601), Hastelloy C 276 (UNS No. N10276), Alloy 20 (UNS No. N08020), Titanium (Grade I & II)

Copper Alloy Lap Joint Flanges

Grade : UNS No. C 10100, 10200, 10300, 10800, 12000, 12200, 70600, 71500, UNS No. C 70600 (Cu -Ni- 90/10), C 71500 (Cu -Ni- 70/30)

Lap Joint Flanges Standard

ANSI : ANSI B16.5, ANSI B16.47, MSS SP44, ANSI B16.36, ANSI B16.48

DIN : DIN2527, DIN2566, DIN2573, DIN2576, DIN2641, DIN2642, DIN2655, DIN2656, DIN2627, DIN2628, DIN2629, DIN 2631, DIN2632, DIN2633, DIN2634, DIN2635, DIN2636, DIN2637, DIN2638, DIN2673

B.S : BS4504, BS4504, BS1560, BS10

OTHER : PLATE, PLATE BLANK

Value Added Services for Lap Joint Flanges

HOT DIPPED GALVANIZING

HEAT TREATMENT

CNC MACHINING

THREADING

Lap Joint Flanges Packaging & Marking

All Lap Joint Flanges are individually covered so that the premium quality of materials is retained and there are no damges in the last stages of production. We also ensure that we deliver our orders promplty and that the quality remains intact.

All Lap Joint Flanges have imprints on them to highlight the specification of the pipes.