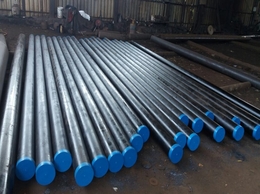

TRIO STEEL IS A LEADING MANUFACTURER, SUPPLIER AND EXPORTER OF ASTM A 106 Grade Pipes.

We provide a complete and best quality range of ASTM A 106 Grade Pipes. ASTM A 106 Grade Pipes are used in constructions, food industry, pharmaceutical industry, petrochemical industry, automotive industry, municipal and decorative purposes. All ASTM A 106 Grade Pipes are individually covered so that the premium quality of materials is retained and there are no damages in the last stages of production.

ASTM A 106 Grade Pipes:

Carbon Steel Pipes are widely used in industries worldwide. The most common category of carbon steel pipes is ASTM A106 Grade Pipes. ASTM A106 Grade Pipes (also known as ASME SA106 pipe) is commonly used in the construction of oil and gas refineries, power plants, petrochemical plants, boilers, and ships where the piping must transport fluids and gases that exhibit higher temperatures and pressure levels.

Size Range:

ASTM A106 Grade Seamless Pipes: 1’’ to 24’’

ASTM A106 Grade Welded Pipes: 16’’ to 72’’

Thickness: 2MM-100MM

Length: 1 Meter to 12 Meters

Chemical Composition:

| C | Si | Mn | P | S | Cr | Mo | Ni | V | CE(IIW) | CE(PCM) | |

| % | % | % | % | % | % | % | % | % | % | % | |

| Min | – | 0.1 | 0.29 | – | – | – | – | – | – | – | – |

| Max | 0.30 | 0.45 | 1.06 | 0.035 | 0.035 | 0.40 | 0.15 | 0.40 | 0.08 | 0.43 | 0.25 |

Mechanical Composition:

| YS (Mpa) | UTS (Mpa) | EL % | YS/UTS | |

| MIN | 240 | 415 | 22 | – |

| MAX | – | – | – | 0.93 |

ASTM A106 Grade Pipes are generally heat treated with normalizing up to 900 DEG C. They can be supplied with a coating like 3LPE Coating, Anti-Rust Coating, or can be supplied Bare. They are supplied with end caps and bundled together to avoid damage in transit. Rexal Tubes is the leading stockiest in India with over 800-ton stock in carbon steel seamless pipe tubes.

We supply the below things along with the pipes:

Documentation

- Commercial Invoice which includes HS Code

- Packing List including net weight and gross weight, number of boxes, Marks and Numbers

- Certificate of Origin legalized/attested by Chamber of Commerce or Embassy

- Fumigation Certificates

- Raw Material Test Reports

- Material Traceability Records

- Quality Assurance Plan (QAP)

- Heat Treatment Charts

- Test Certificates certifying NACE MR0103, NACE MR0175

- Material Test Certificates (MTC) as per EN 10204 3.1 and EN 10204 3.2